Highlights

- Parts designed even for small series

- Complex shapes at low cost

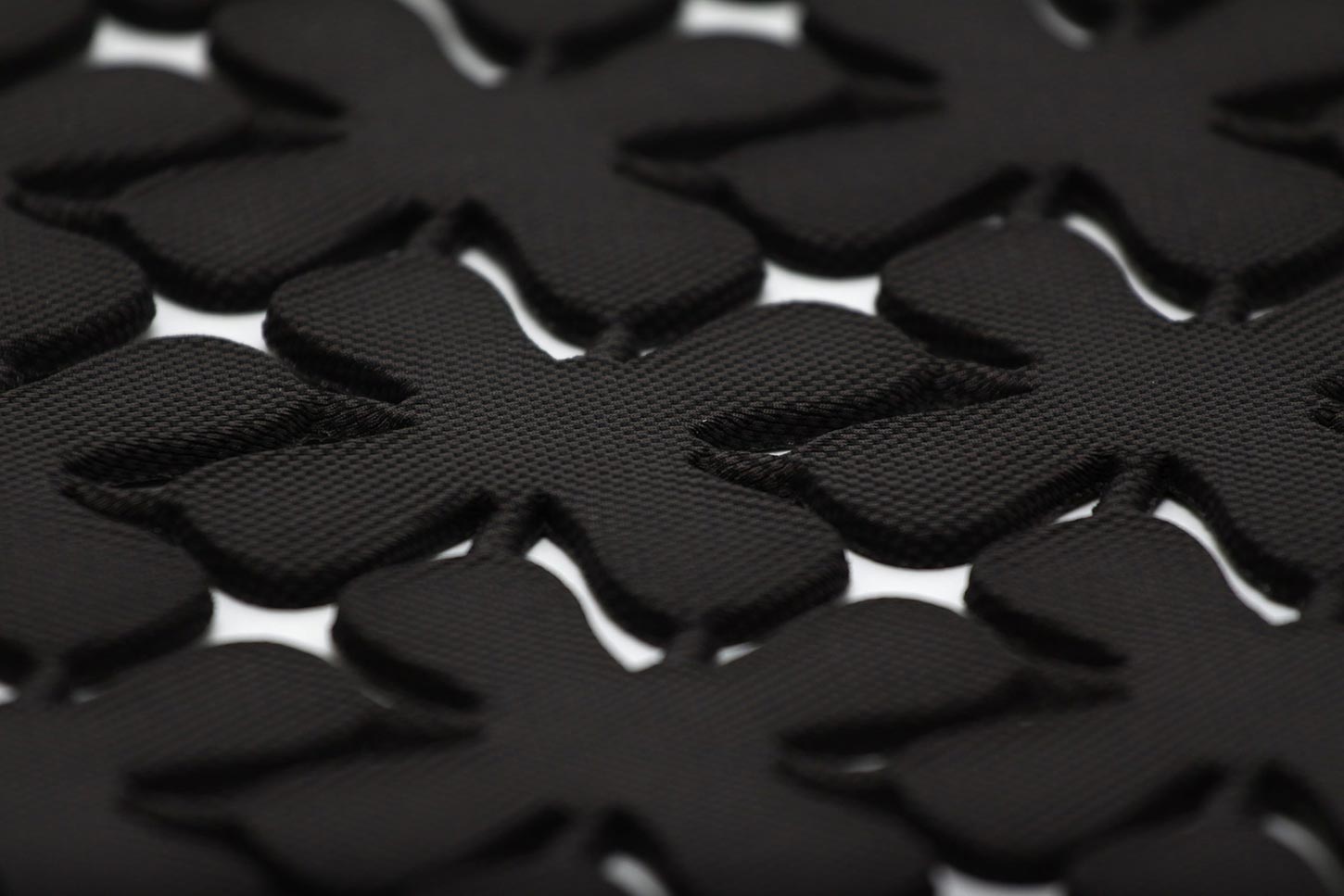

- Vast choice of bondable fabrics or materials

- High protection

- Perfect fit with any supports

- Non-allergenic

- Customisation

- Can be used in all sectors of production

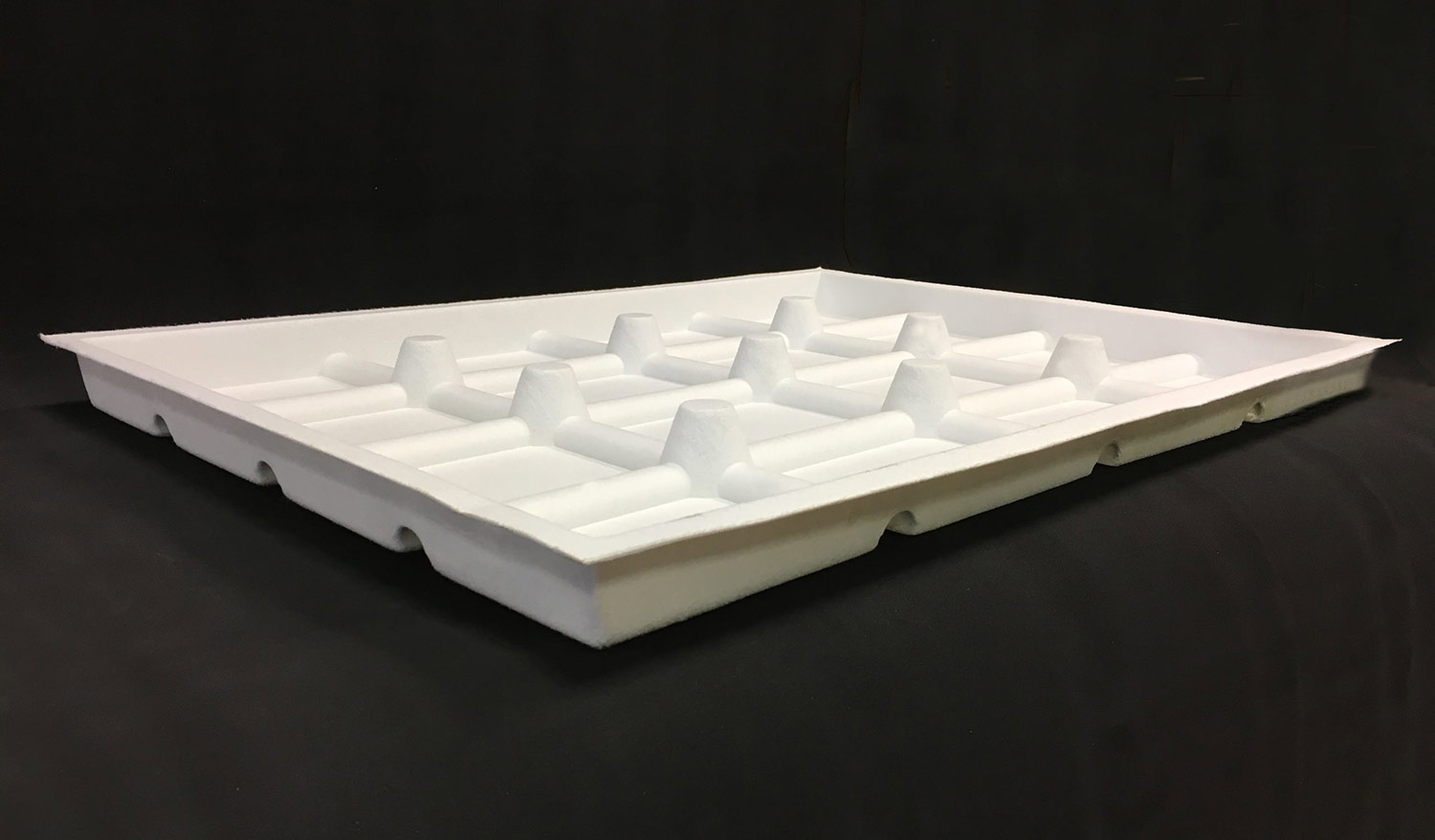

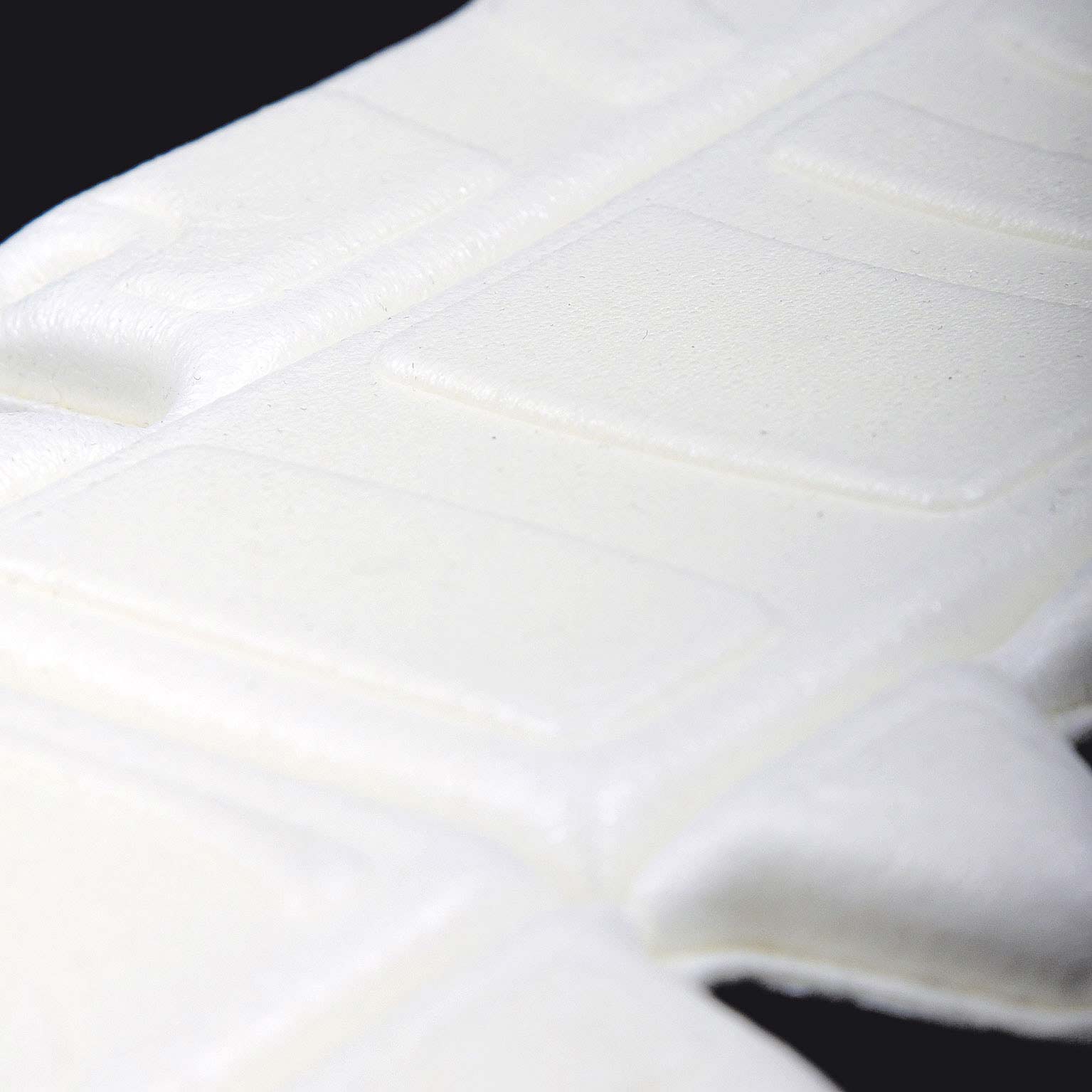

Thermoformed products

Expanded polyethylene

DESCRIPTION

Thermoforming is an alternative processing technique to traditional and onerous moulding processes. It enables the complex shapes required by various sectors of the manufacturing industry to be created even in small series and at low cost.

Our thermoformed components are widely used as:

– Protection. Knee-pads, protection for skiers and motorcyclists;

– Packaging. Measured according to the object to be contained, and perfectly in accordance with it, a thermoformed package attains standards that cannot be achieved with cold mechanical processing. The possibility of bonding thermoformed components to high-quality coverings is a much-appreciated benefit for brand packaging;

– Fashion. Thermoformed components, often customised with logos and bonded to leather and fabrics, are used to create travel items (leather goods), bags and accessories;

– Orthopaedics. Thermoforming enables the production of braces, corsets, supports and insoles that are “anatomically” adapted to the parts of the body.

SUPPLY

Our thermoforming division can support the customer right from the design phase, identifying and bonding with fabrics or protective films.

USES

INDUSTRY

- Technical and protective packaging

- Automotive inserts and seals

- Orthopaedic seals and protection

- Leather goods/accessories

- Padding, including protective Sporting protection

COMMUNICATION

- Creative/luxury packaging